Vacuum Forming

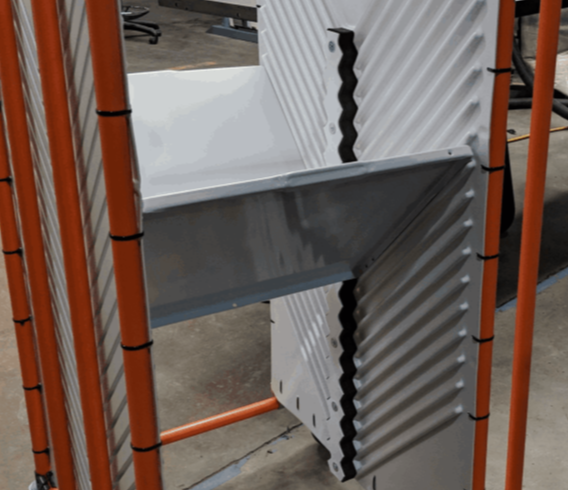

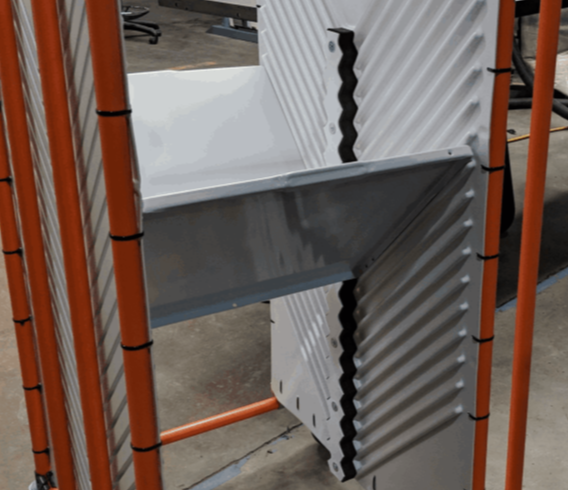

By integrating vacuum forms into our material transfer carts, we are able to save customers time and money. Vacuum forms can be made much more quickly than other conventional methods of parts division on a cart. Mashak Engineering Solutions builds all of our own molds in house, which translates to a lower cost to the customer and a quicker turnaround time.

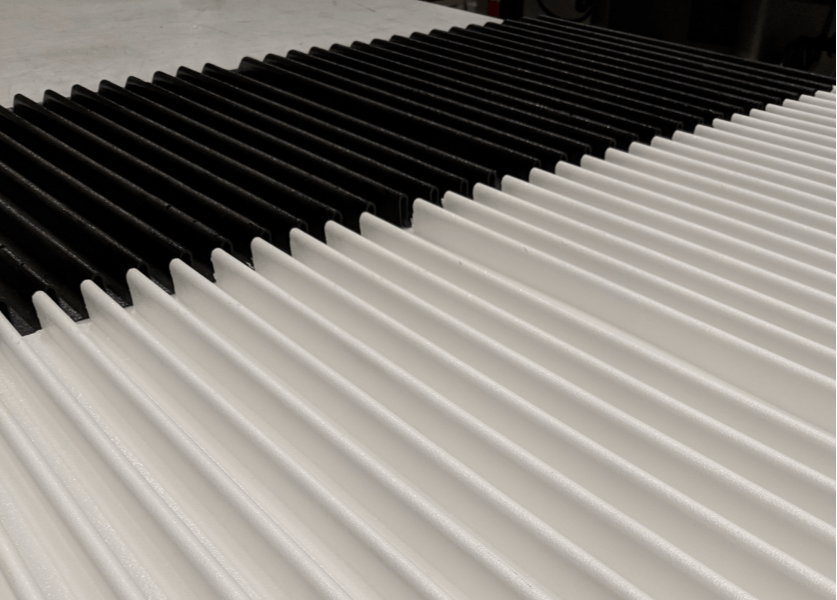

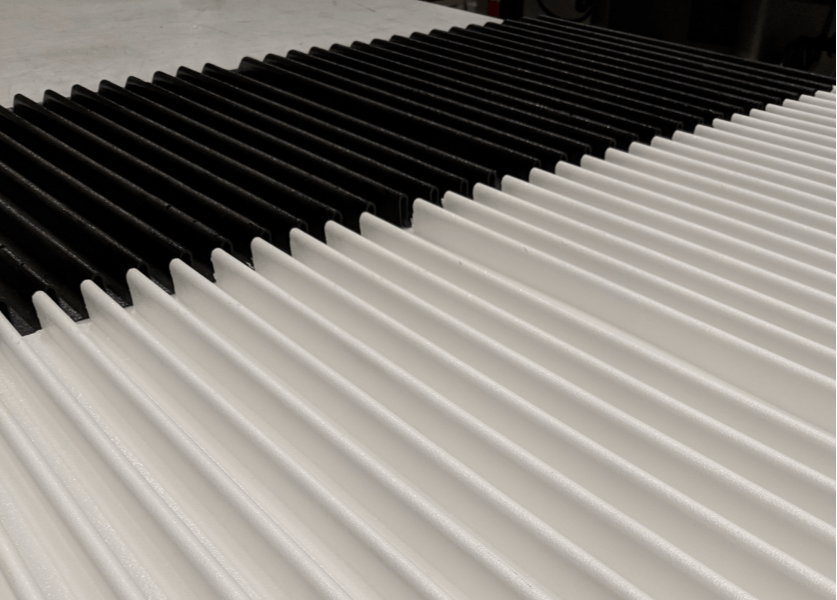

We use a variety of thermoformable plastics in our vacuum form process, but the majority of what we use is ABS. When we design and build our molds, we take into account wall-thinning in the final product. With this in mind, by using ABS as our primary material for pulling the vacuum forms, we increase durability over time. After thousands of parts rubbing and sliding on our vacuum forms, the hairstyle surface finish is still intact.

Over time everything wears out and accidents happen. It's reassuring to know that you can have a replacement quickly. Damaged or worn out vacuum forms can be removed quickly and replaced with new ones from us. Being able to replace a whole panel at once saves time and gets you back up and running with minimal downtime and effort.

How to make a free website - Look at here